Photovoltaic special sealant/FQG651

FQG651-Photovoltaic module dedicated sealant is a single component neutral curing RTV Silicone Sealant. This kind of sealant has good adhesion to aluminum, toughened glass, composite back material, and junction box PPO material, and can be used for bonding and sealing of solar cell assembly frames and junction boxes.

Product feature

1、Use of advanced sealant production technology and high purity imported basic raw materials, special technology to eliminate residual unsaturated and low boiling matter effectively with environmental protection, low odor, non-corrosive characteristics.

2、Excellent bonding property for special aluminum, toughened glass, composite back material, junction box PPO material.

3、Moderate hardness, low moisture permeability.

4、Through the double "85" high temperature and humidity test, aging resistance test, cold and hot impact test, with yellowing resistance, moisture resistance, environmental corrosion resistance, mechanical and thermal shock resistance, shock resistance and other functions.

Main application

1、Used for solar cell assembly frame and junction box bonding and sealing.

Package

Plastic drum , N.W is 310ml ;

Composite soft film package, N.W is 400ml. 5 gallon drum package, N.W is 25 KG

55 gallon drum package, N.W is 270 KG

Bonding surface pretreatment method

1、All surfaces shall be clean and dry and remove all grease and contamination

that may affect bonding. Suitable solvents include isopropyl alcohol, acetone,

or methyl ethyl ketone.

2、The adhesion of certain plastics requires special treatment of the surface, such

as polypropylene and teflon, which require chemical etching or plasma treatment

to achieve optimal adhesion.

Expiry date and storage

The sealant is valid for 9 months (from the date of production) when the packaging is in good condition and stored in a cool and dry place below 27°.

FQ651 Neutral sealant is easy to react with moisture in the air and cure , so please seal the package when we no longer use it, it is easy to form a clogging seal in the sealant cartridge or tube end, which can be easily cleaned and does not affect the remaining composition.

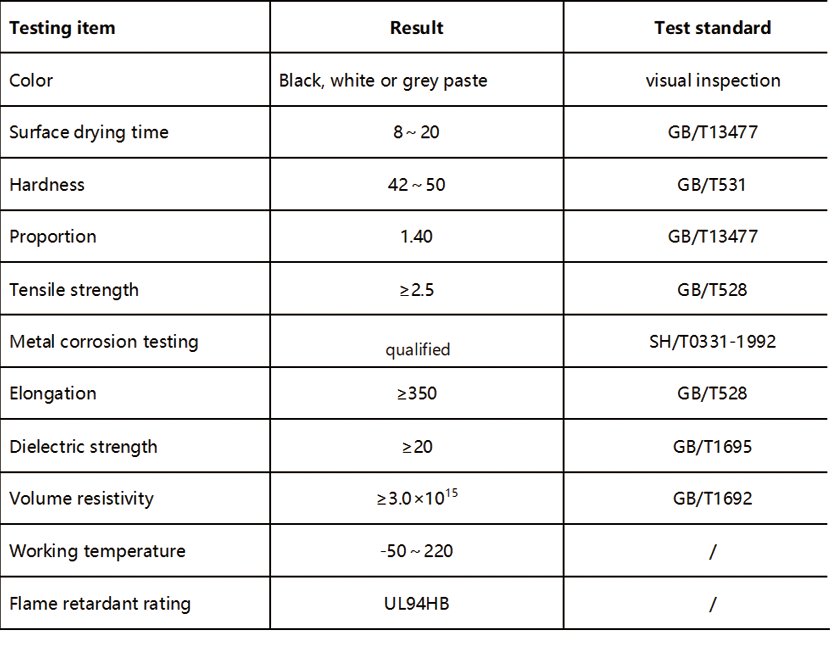

Typical technical data: